Q. What is the process of offset printing? What kind of machines do you need and why is it so expensive to set up?

The Process of Offset Printing

Offset printing is a printing technique where an inked image is transferred (or “offset”) from a plate to a rubber blanket and then to the printing surface. The process of offset printing is as follows:

1. Prepress Preparation starts with:

- – Design and Typesetting: The document to be printed is designed and typeset using desktop publishing software. The final design is then converted into a format suitable for printing (usually a high-resolution PDF (Print PDF)).

- – Platemaking: The digital file (Print PDF) is used to create printing plates. Each color (typically CMYK) requires a separate plate. The plates are usually made from metal and are created using a photomechanical or laser process.

2. Next comes – Setting Up the Press:

- – Mounting Plates: The printing plates are mounted onto the plate cylinders of the printing press.

- – Ink and Water Balance: The press is loaded with ink and water. The plates are dampened with water first, which adheres to the non-image areas, and then ink is applied, which adheres only to the image areas. This process requires skill to produce a quality product. You want to engage an offset printer who understands what type of end product you want.

3. The Printing Process:

- – Ink Transfer: The inked image on the plate is transferred to a rubber blanket on a blanket cylinder and then from the blanket cylinder to the printing substrate (paper or other materials). The rubber blanket conforms to the printing surface, ensuring a high-quality image transfer.

- – There are Multiple Passes: For color printing, the paper typically passes through several units of the press, each applying a different color of ink. This is known as a four-color process [Cyan, Magenta, Yellow, and Key (CMYK)].

4. The Post-Press Operations:

- – Drying: Depending on the type of ink and paper, the printed sheets may need to dry before further processing.

- – Finishing: The printed sheets are cut, folded, bound, or otherwise finished to create the final product.

5. The Types of Machines Used in Offset Printing are:

- 1. Plate-Making Machines:

- – CTP (Computer-to-Plate) Systems: These are used to create high-resolution plates directly from digital files, eliminating the need for film.

- 2. Offset Printing Presses:

- – Sheet-Fed Presses: Prints on individual sheets of paper. Suitable for smaller quantities and a variety of paper types and sizes.

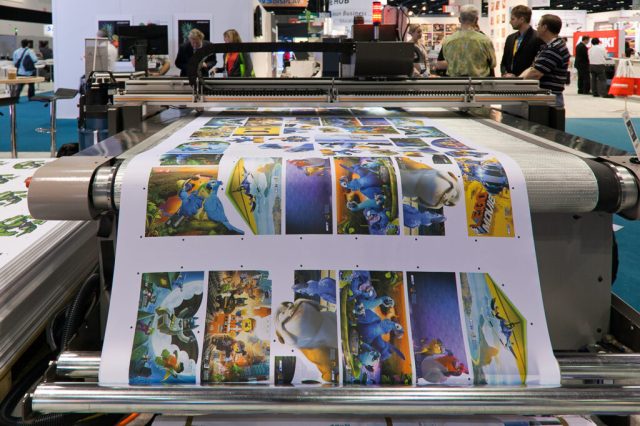

- – Web-Fed Presses: Prints on continuous rolls of paper. Suitable for high-volume runs, such as newspapers, magazines, and catalogs.

- 3. Finishing Equipment:

- – Cutting Machines: These are used for trimming printed sheets to the desired size.

- – Folding Machines: – Used for creating folded materials like brochures and booklets.

- – Binding Machines: – These are used for assembling books, magazines, and other bound materials.

- – Laminators, Die-Cutters, and Embossers:- These are used for additional finishing processes.

Q. Why Is Offset Printing So Expensive to Set Up?

- 1. The Initial Equipment Costs:

- – Offset Printing requires High-Cost Machines: – Offset printing presses and plate-making equipment are expensive. Industrial-grade machines cost hundreds of thousands to millions of dollars.

- – Maintenance and purchasing Consumables: The ongoing costs of maintaining the machines and purchasing consumables like plates, inks, and cleaning supplies are significant.

- 2. The Process of Platemaking:

- – Creating Plates: Each color requires a separate plate. Creating these plates is a detailed and costly process.

- – High Quality: Plates must be very high quality to ensure accurate and precise printing, adding to the cost.

- 3. The Setup Time:

- – Calibration and Alignment: The Offset Printer will spend significant time calibrating the press and aligning the plates, especially for multi-color jobs. Any error can lead to waste and rework. You need skilled printers to work this process.

- – Test Prints: Multiple test prints are often required to achieve the correct color balance and quality, which can consume materials and time.

- 4. Labor Costs:

- – Skilled Operators: Trained personnel are needed to operate and maintain the presses and their expertise comes at a premium.

- – Manual Adjustments: Many aspects of offset printing require manual adjustments and supervision to ensure quality. Hence, the requirement for skilled operators to ensure good results.

- 5. Economies of Scale:

- – Large Runs: Offset printing is most cost-effective for large print runs because the setup costs are spread over a large number of copies. For small runs, the per-unit cost remains high due to the initial setup expenses.

Q. What is the process of digital printing of books? Is it easy to set up?

The Process of Digital Printing of Books

Digital printing is a method of printing from a digital-based image/file directly to a variety of media. It is especially suitable for short runs and on-demand printing. Following is a short overview of the process for digital printing of books:

1. Prepress Preparation:

- – Document Preparation:- The manuscript is prepared using word processing or desktop publishing software, and then converted into a print-ready PDF. This PDF includes all text, images, and layout settings.

- – Proofing:- Digital proofs can be created and reviewed on-screen or printed on a small scale to check for errors and ensure the layout looks as expected.

2. Printing Process:

- – The Digital Printing Press: – The print-ready PDF is sent directly to a digital printing press. There are two main types of digital presses:

- – Laser Printers: Use toner-based technology similar to office laser printers but on a larger scale.

- – Inkjet Printers: Use liquid ink sprayed onto the paper, suitable for high-quality color printing.

- – Variable Data Printing: Digital printing can handle variable data, allowing for customization of each printed piece (e.g., personalized names or addresses).

3. Post-Printing:

- – Collating: – The printed sheets are collated into the correct order for binding.

- – Binding: – Common binding methods for digitally printed books include perfect binding, saddle stitching, and spiral binding.

- – Finishing: – Additional finishing touches such as trimming, laminating covers, or adding protective coatings.

Q. Is Digital Printing Easy to Set Up?

Digital printing is generally easier and more straightforward to set up compared to traditional offset printing. This is why:

1. Lower Initial Costs:

- – Equipment: Digital printing presses are typically less expensive than offset presses, making them more accessible for small businesses and self-publishers.

- – No Plates Needed: Digital printing does not require the creation of printing plates, which reduces setup time and cost.

2. Quick Turnaround:

- – On-Demand Printing: Digital printing can handle short runs efficiently, allowing for printing on demand. This means you can print only what you need, reducing waste and storage costs.

- – Fast Setup: Sending a digital file to the printer is quick, and there is minimal setup time compared to offset printing.

3. Ease of Use:

- – User-Friendly Software: Most digital printing setups use user-friendly software that integrates with common design tools, making it easy to prepare files for printing.

- – Automated Processes: Many digital presses have automated features for alignment, color management, and finishing, reducing the need for manual adjustments.

4. Flexibility:

- – Customization: Digital printing allows for easy customization and variable data printing, which is ideal for personalized books or limited editions.

- – Short and Long Runs: While offset printing is more cost-effective for large runs, digital printing can handle both short and long runs with equal efficiency.

5. Proofing and Quality Control:

- – Digital Proofs: Proofs can be generated quickly and at a low cost allowing for easy revisions and quality checks before the final print run.

- – Consistent Quality: Digital printing offers consistent quality from the first copy to the last, with less risk of variation compared to offset printing.

Q. Are there benefits to offset printing in this digital age?

Offset printing still offers several benefits in our digital age, particularly for certain projects and print runs. Here are 7 key advantages of offset printing:

- 1. Cost Efficiency for Large Print Runs:

- – Economies of Scale: Offset printing becomes more cost-effective as the print run increases. The initial setup costs (plates and press setup) are high, but the per-unit cost decreases significantly with larger quantities of print jobs.

- – High Volume: Offset Printing is ideal for printing large quantities of books, magazines, newspapers, brochures, and other materials where the demand justifies the setup costs.

- 2. Superior Print Quality:

- – High Resolution: Offset printing produces high-resolution prints with sharp details and clear images. The quality is often superior to digital printing, especially for fine details and color gradients.

- – Color Consistency: Offset printing achieves consistent color reproduction across the entire print run, which is critical for brand colors and high-end publications.

- 3. Color Accuracy and Range:

- – Pantone Colors: Offset Printing can use Pantone or spot colors to achieve specific hues that are difficult to replicate with digital printing. This is important for brand consistency and specific color requirements.

- – CMYK Accuracy: Offset printing handles complex color jobs more accurately, ensuring precise color matching and consistency.

- 4. Wide Range of Paper and Ink Options:

- – Paper Variety: Offset Printing can print on a wider range of paper types, weights, and finishes than most digital presses. This includes specialty papers and unique textures.

- – Specialty Inks: The ability to use specialty inks such as metallic, fluorescent, and varnishes, which can enhance the visual appeal of the printed materials.

- 5. Durability and Longevity:

- – Long-Lasting Prints: Offset printing typically uses more durable inks that are less prone to fading and wear over time, making it suitable for materials that need to last longer.

- – High-Volume Durability: The equipment used in offset printing is designed for long runs and can maintain quality over large volumes without degradation.

- 6. Advanced Finishing Options:

- – Special Finishes: Offers a variety of finishing options such as embossing, debossing, foil stamping, and die-cutting, which can add a premium touch to printed materials.

- – Binding Options: It allows for more binding options, particularly for high-volume projects, ensuring professional and durable results.

- 7. Flexibility for Large Formats:

- – Large Format Printing: Capable of handling larger print sizes and formats, making it suitable for posters, large brochures, maps, and other oversized prints.

Q. When can an Author Choose Offset Printing?

1. - For Large Print Runs: When printing thousands of copies, offset printing is more economical due to the lower per-unit cost.

2. - For High-Quality Requirements: For projects requiring the highest print quality, color accuracy, and consistency.

3. - For Specific Color Needs: When precise color matching and the use of Pantone or specialty inks are required.

4. - For Specialty Papers and Finishes: When the project involves unique paper types or advanced finishing techniques that digital presses may not support.

In Summary:

While Digital Printing is ideal for short runs, on-demand printing, and personalized content, Offset Printing remains highly relevant for large print runs, projects demanding superior quality and color accuracy, and jobs requiring specialty finishes and papers.

Each printing method has its strengths, and the choice between offset and digital printing depends on the Project’s specific needs, the desired quality, and the print volume.

Digital printing of books is a more accessible and flexible option compared to traditional offset printing. It requires less initial investment, has a quicker setup time, and is user-friendly, making it ideal for small print runs, on-demand printing, and projects requiring customization. The process involves preparing a digital file, sending it directly to a digital press, collating, binding, and finishing the printed materials. This makes it particularly suitable for self-publishers and small publishers looking to produce high-quality books efficiently and cost-effectively.

Leave a comment